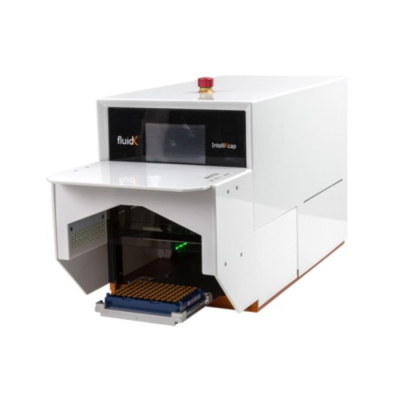

IntelliXcap™ automated screw cap decapper/recapper acoustic is next-generation, engineered for increased throughput, ease of use and high system reliability, making the system ideal for any laboratory managing compound libraries or biological sample stores working with Azenta Life Sciences Acoustic Sample Tube - Echo® Qualified Consumable. Rapid decapping and capping, compatible with multiple sample storage tube types from a range of tube manufacturers in 96 format. IntelliXcap™ automated screw cap decapper/recapper acoustic is capable of de-capping a complete rack of 96 tubes in as little as 20 seconds. Automation and high speed reduces sample handling time, increasing sample throughput workflow. Ideal for medium to high-throughput laboratories managing compound libraries, biobanks or other biological samples.

Additional camera module, was developed for validation of Azenta Life Sciences acoustic sample tube capping and uncapping by using a rack vision system and Azenta Life Sciences Decoding Software (PC to run Decoding Software not included).

Specially designed for use with Azenta Life Sciences Acoustic Sample Tube - Echo Qualified Consumable

Extremely fast, works with multiple sample storage tube types from a range of tube manufacturers

Suitable for use with 96-format racked tubes

Capable of de-capping a complete rack of 96 tubes in as little as 20 seconds

Automation and high speed reduces sample handling time, increasing sample throughput workflow

Ideal for medium to high-throughput laboratories managing compound libraries, biobanks or other biological samples

Validation of tube capping and uncapping using rack vision system, equipped with an additional camera module that uses an image algorithm to detect the presence of caps, before and after the decapping/capping process

Features a unique, fully automated, interchangeable cartridge cap driver system

Cartridges allow change between different tube types in less than 2 minutes

No need for specialist intervention to change cartridge drivers

Control is via a quick installation, easy-to-use touch panel

Quick installation, easy-to-use touch panels bring instant control

Cap detection

Wide operating temperature range of 5 to 40°C

Electric torque control means less persistent wear on cap drivers

Sample rack stage extension facilitates fully automated workflow integration

Includes base unit, IntelliXcheck™ module and 1 x 48-8013-04 (acoustic cartridge)